- An ISO Certified Company 2009:2015

- Mobile: +91 9725558549

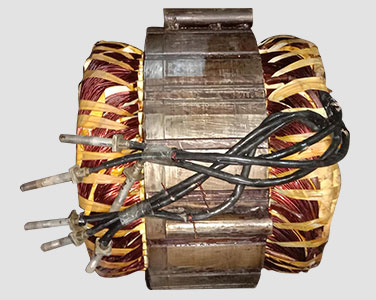

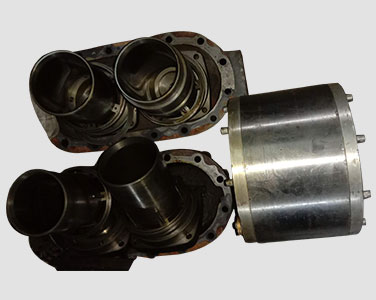

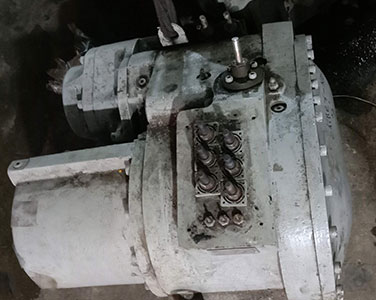

Screw Compressor Repairing Services

Compressors

The major parts of a water cooled chiller are the compressors, the evaporator heat exchanger (piping circuit #1) and the condenser heat exchanger (piping circuit #2) so for any fault head onto the services of screw chiller compressor repairing. In a chiller plant design there are two separate piping circuits.

Circuit #1

A chiller produces cold water that is typically circulated (pumped) to cooling coils that are inside air conditioning units. This is called the chilled water piping circuit.

The air conditioning unit fan takes air from a room and blows this air across the cooling coil to produce colder air and then circulates this colder air through a duct system to cool the room.

Once the cold water from the chiller cools the air, it becomes warmer, and it must be circulated back to the chiller so that it can become cooler again.

Circuit #2

The refrigerant becomes warmer and it rejects its heat to the cooling tower (or condenser water) piping circuit, so that the entire process can start over once the water cools as a chiller uses a refrigerant to cool the water. For any queries you can head on to screw chiller compressor repairing in Ahmedabad.

The basic design consists of a chiller or multiple chillers, chiller water pumps for the chilled water piping circuit, a cooling tower or towers and cooling tower pumps for the cooling tower water piping circuit.

There is a cooling tower which is considered a heat rejection device, in a water cooled chiller plant design and by circulating water through the chiller and then takes this warmer water and rejects this heat to the tower it takes the unwanted heat from the chiller. Into the atmosphere, the tower then takes the heat from the water and rejects this heat. It is called the condenser water circuit, this is the second piping circuit.